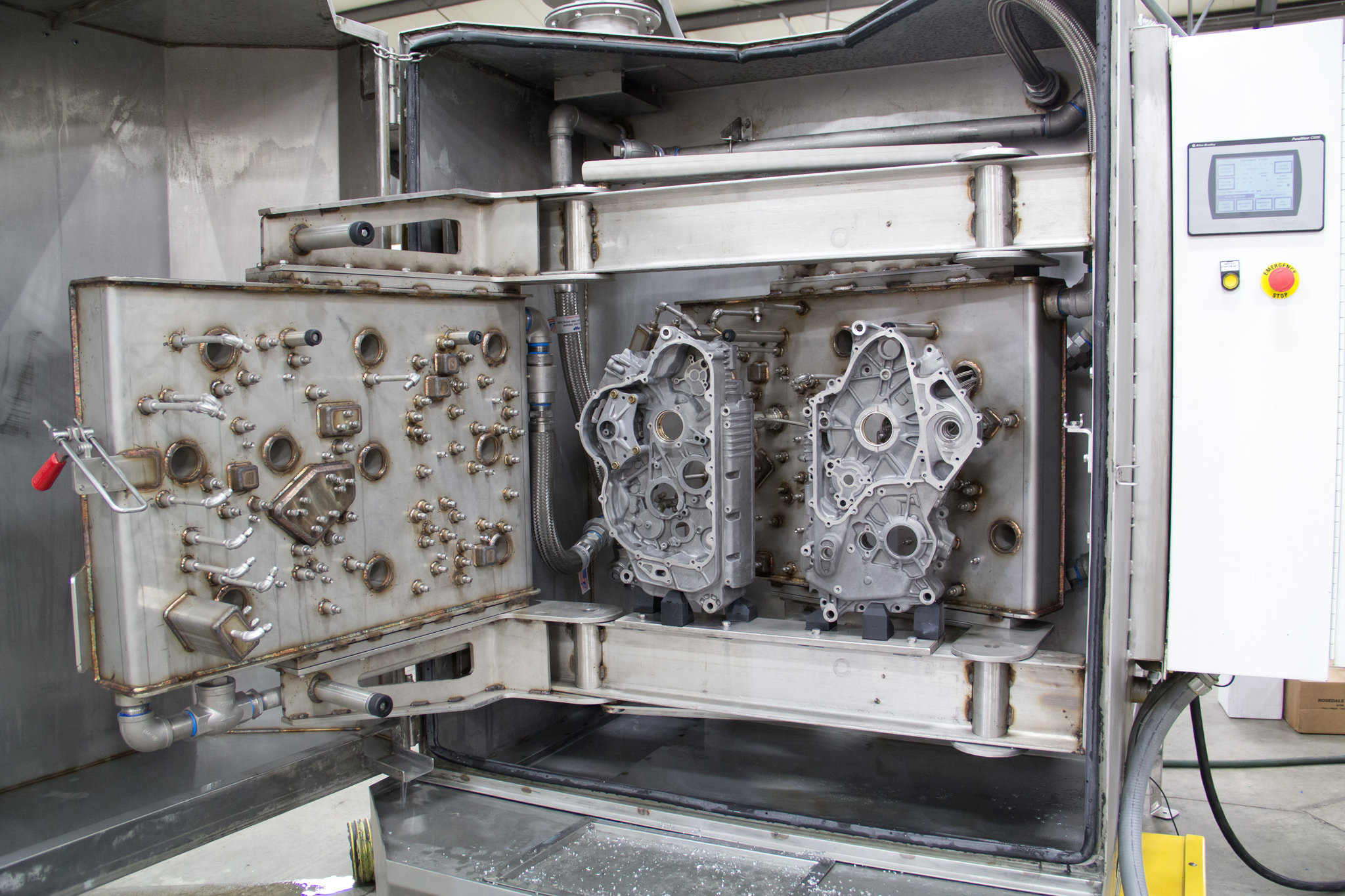

For manufactures producing parts at low volume but with critical cleaning requirements, a stationary fixture washer is the answer. Alliance’s “stationary fixture” cabinet-style washers offer the option of interchangeable part fixtures to better accommodate various part programs with different configurations. This can equal a significant cost advantage when the part program changes; instead of a complete re-tooling or purchasing of an entirely new machine, the fixture can be changed. These fixtures are fabricated from stainless steel and designed specifically to the part to be cleaned. The entire fixture can be installed and bolted into the washer, and then removed and replaced with a different fixture for another part program. Utilizing fixtures in a parts cleaning system allows for parts with strict cleanliness specifications to have targeted sprays directed at critical areas, such as blind holes and cavities. Typically fixtures are seen on inline indexing washing systems, but when the customer’s needs call for a machine that is more compact or takes up less floor space, with a lower production volume, a stationary fixture cabinet washer is a viable solution.