Customer Background

The customer is a foreign manufacturer of vehicle braking system components and aluminum products. Additional plants are located in the US as well as around the world.

Challenge

The customer needed a washing system to clean and dry both the left-hand and right-hand cast iron brake calipers. The parts needed to exit the machine at a rate of 25 seconds per set of parts.

Solution

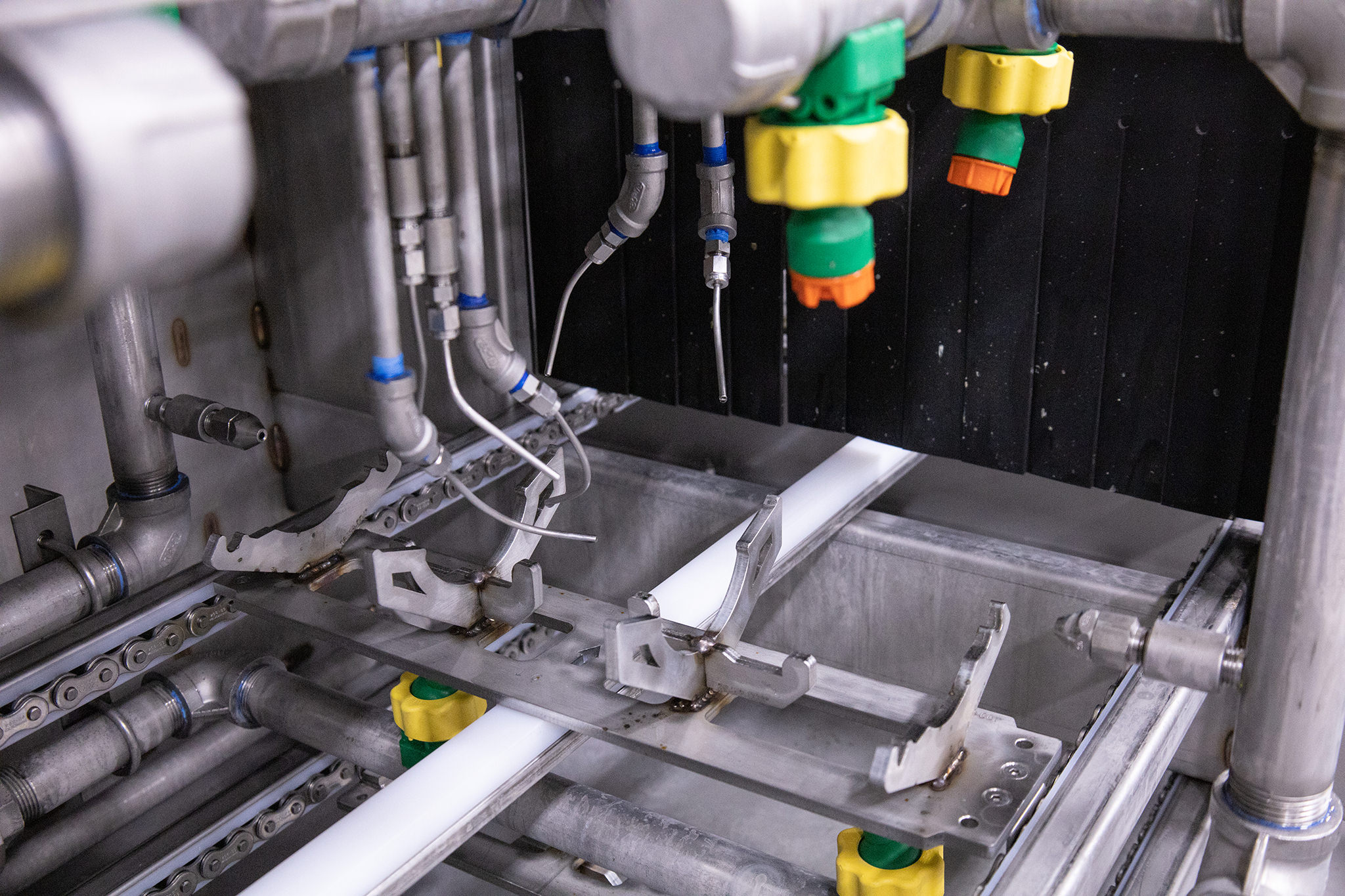

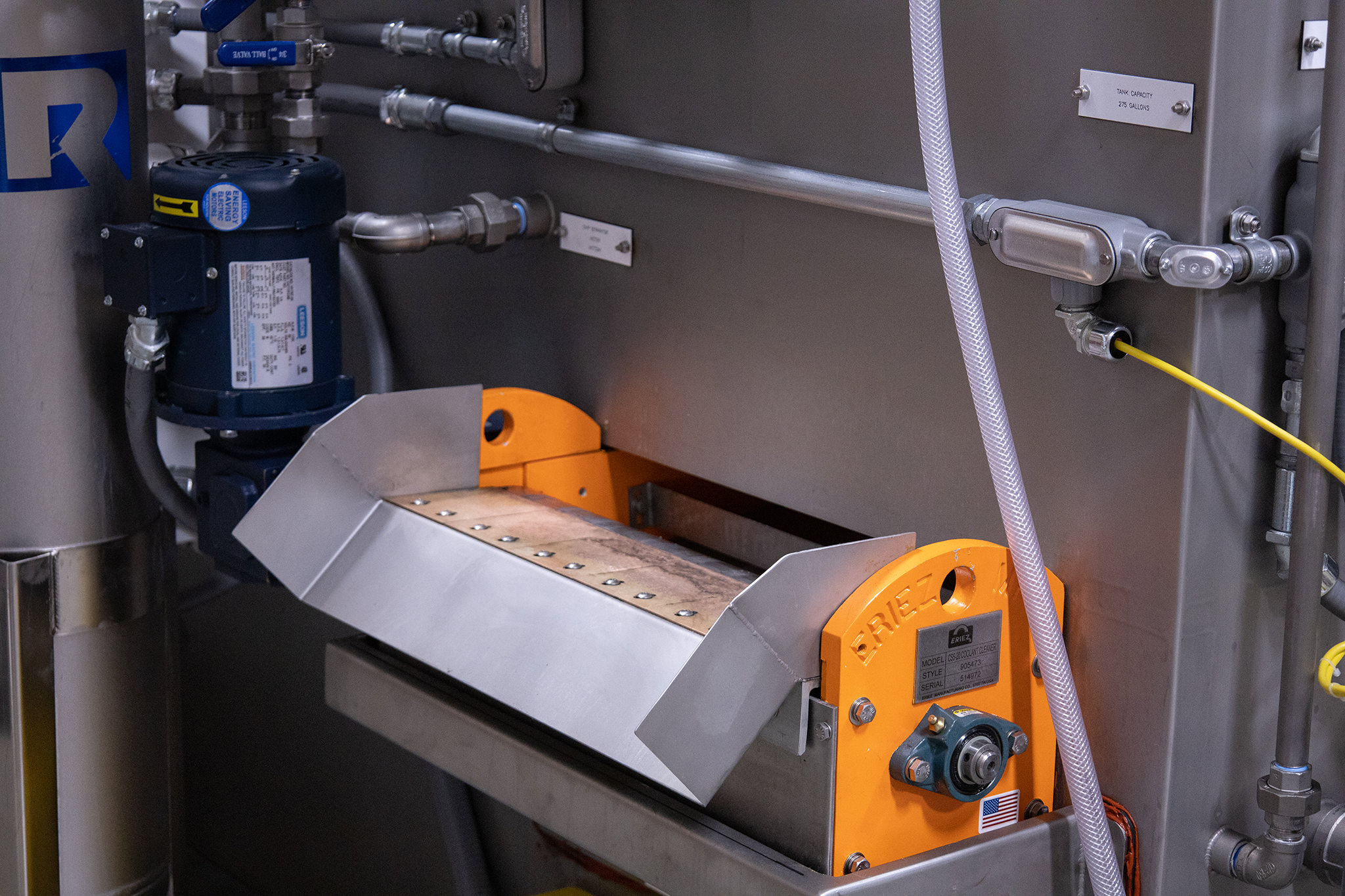

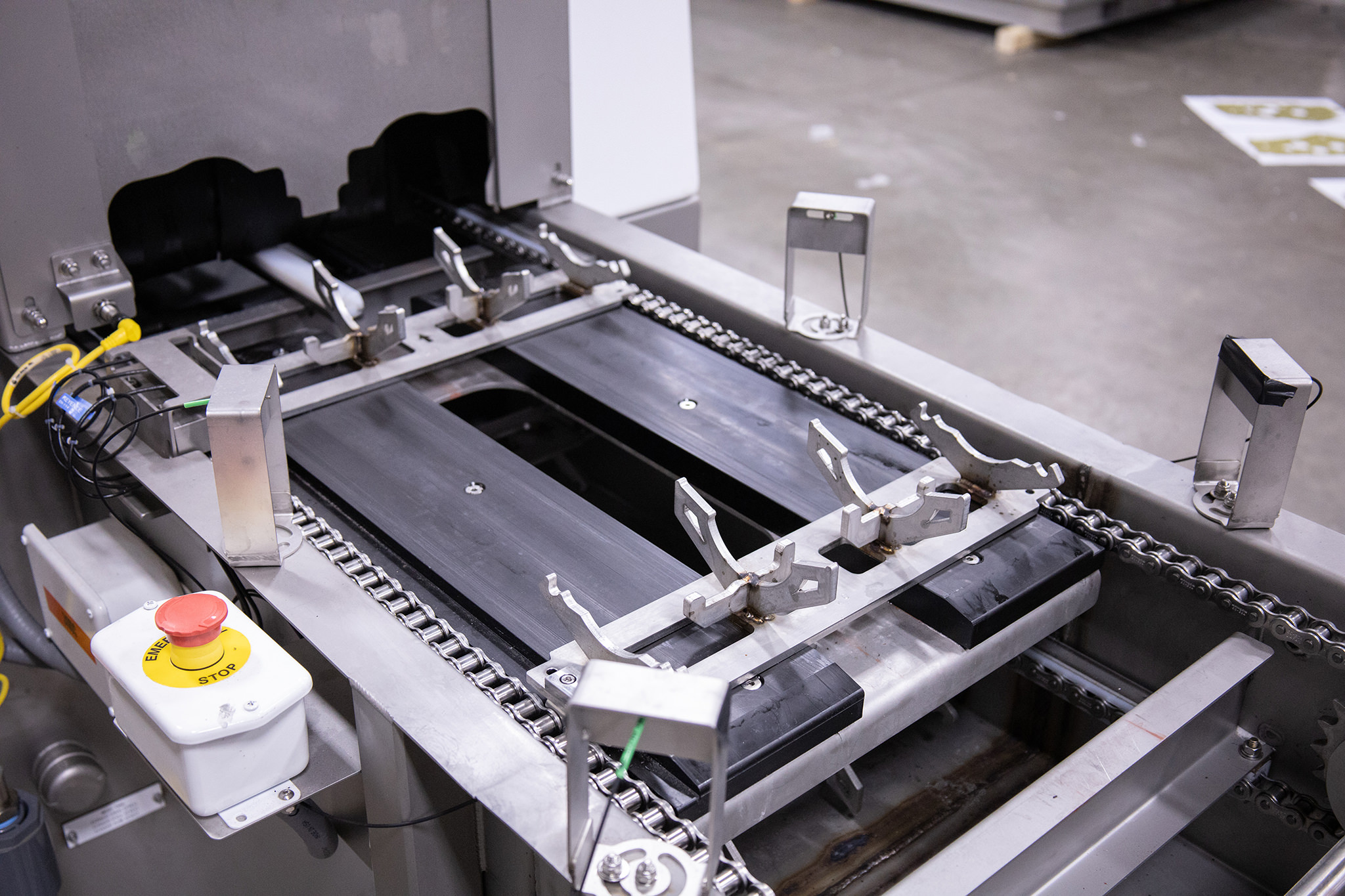

Alliance engineered an indexing cleaning system to wash and blow off moisture from the parts. A servo motor allows the part fixtures to stop in each zone for targeted cleaning and drying of the part features. This machine was designed for automated part loading and unloading, and each of the 20 part fixtures could accept either the left-hand or right-hand brake calipers. A custom part profile plate will shut down the servo drive in the event of a mis-load. There are targeted spray nozzles in the wash index zone. In the ambient blow-off zone, air knives remove gross amounts of moisture while a timed compressed air cycle targets interior passageways of the parts. An optional magnetic chip separator was incorporated to aid in removing ferrous metal contaminate from the wash tank.

Cleaning Method

Aqueous cleaning was chosen due to the need to flush out and dry specific part features, and because the inline process was required for the customer’s existing plant automation systems. This is also ideal for the high production requirement.