Industrial parts cleaning systems typically utilize one of two methods for removing excessive steam and air from the machine. Steam is generated during the part cleaning process and must be removed or recirculated back into the machine in order to prevent excessive humidity from being released into the customer’s production area.

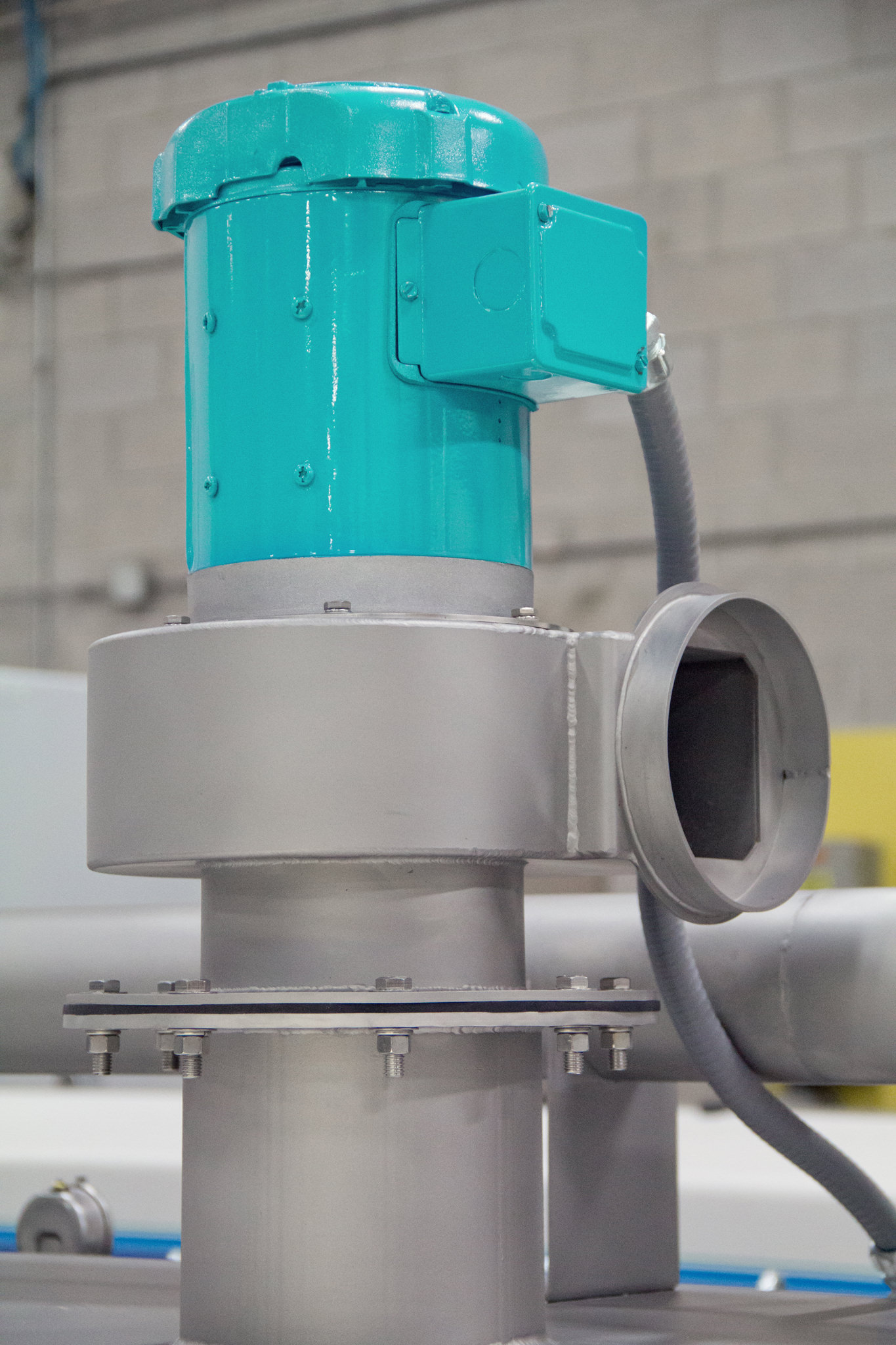

Removing steam and air from the machine can be accomplished by either installing an industrial steam exhaust fan package with an external duct that is routed through the roof of the facility and released outside, or by installing a mist collection system that will extract the majority of the moisture from the exhaust air stream and return the extracted water back into the machine tank reservoir for reuse while the exhaust air is released back into the facility.

The advantage of utilizing an industrial steam exhaust fan package is that the steam and humidity is routed to the outside of the facility. This will prevent the steam’s heat and humidity from being released back into the production area, which could cause potential issues in the surrounding work environment. The disadvantage of incorporating an exhaust fan package is the additional costs associated to install the external ductwork to the outside of the facility.

The advantage of utilizing a mist collection system is that no external ducting or roof penetration is required. This allows the mist collection machine system to be installed at a location within the facility which prohibits external ducting, or allows the machine to be portable and used in different locations as production requires. The disadvantage of a mist collection system is that the equipment costs more than an exhaust fan package, along with releasing humid air back into the work environment. Mist collectors will reduce the volume of moisture in the exhaust air stream but they do not dehumidify the exhaust air.

Exhausting the excessive steam and air from industrial parts washers is critical in producing both clean and dry parts. The customer must weigh both pros and cons of each exhaust system and decide which package offers the best solution to fulfill their manufacturing requirements.