Customer Background

Global supplier of aluminum die-cast components, specializing in powertrain and automotive components. Die-cast solutions include: product design, simulation, testing, rapid prototyping, and production facilities.

Challenge

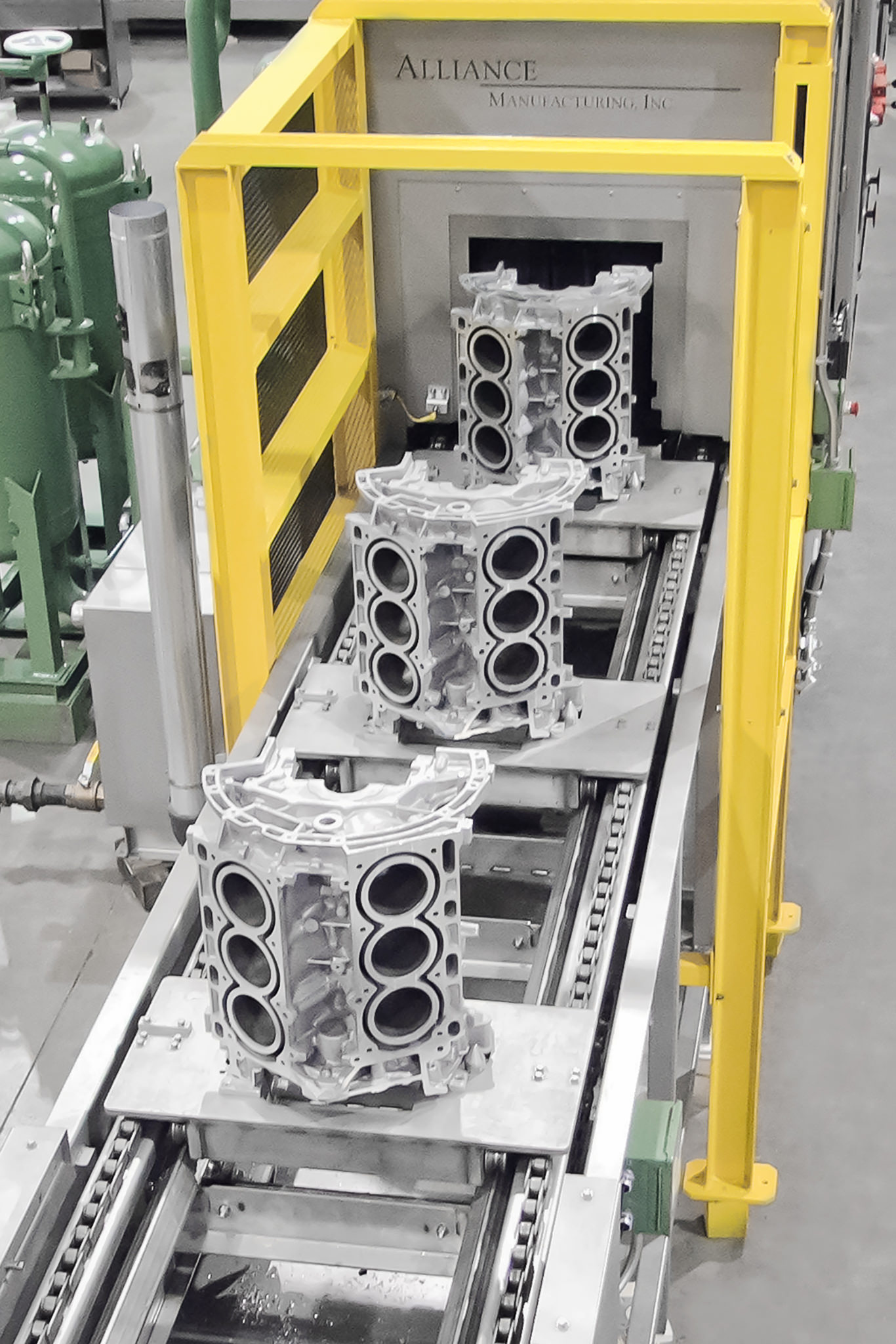

The customer was looking for a system for cleaning rough machined V-6 engine blocks prior to leak test. The parts washer needed to be capable of processing one part approximately every 35 seconds, each part weighing approximately 60 lbs. The engine block cleaning system would be used for intermediate cleaning to remove chips and coolant.

Solution

Alliance provided the customer an Aquamaster CC-1800X indexing conveyorized parts cleaning system for V-6 engine blocks. The machine included wash and blowoff process zones. Heavy-duty stainless steel part fixtures located on 42″ centers were provided to hold one (1) engine block per fixture. A servo-controlled indexing conveyor equipped for automated part loading and unloading by pick-and-place was provided. Pneumatically actuated spray and blowoff manifolds positioned above designated fixture stop locations are lowered for cleaning and blowing off leading and trailing engine block surfaces.