Conveyor Dip Parts Washers

Aquamaster DP

Call us: 1-800-969-7960

The Aquamaster CB-DP industrial conveyor hot dip tank parts washers are designed to clean small, high-volume, non-precision parts. Dip and spray washers are ideal where continual throughput is required within a small footprint.

Request a Quote

Let our team configure the right parts washer for your application.

Alliance’s exclusive “Full Access” fiberglass canopy (U.S. Patent No, 5,630,435) provides unobstructed access to the interior of the machine. All parts cleaning equipment requires regular routine maintenance, and the “Full Access” canopy design provides greater access for maintenance and process adjustment.

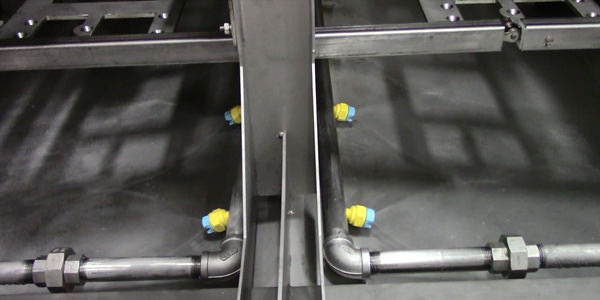

The solution tanks on the Alliance parts washers are constructed of heavy gauge, Type 304 stainless steel for extended equipment life. Tank bottoms are sloped to allow for complete drainage.

A hinged, gasketed clean-out door on the solution tank provides access to the tank interior for periodic maintenance. The door frame is flush to the tank bottom to facilitate easy tank cleaning. The tank bottom is pitched to the drain on the opposite side to prevent residual water from draining out of the clean-out door.

Our new pull-out spray header design allows for quick and easy access to spray nozzles for cleaning and adjustments. With a few simple steps, both upper and lower spray manifolds can be completely pulled out of the machine and just as easily be put back into operation without the need for tools or complicated instructions.

Periodic maintenance of the nozzles is important for optimum machine performance. Clip-on spray nozzles allow for quick and easy removal, cleaning, and adjustment without the need for tools. Nozzles are made of polypropylene and are available in a variety of sizes and flow rates/angles.

Stainless steel nozzles have a standard NPT male thread and are screwed directly to interior spray piping. Stainless steel nozzles may be used in place of or in addition to PPRO spray nozzles.

Additional nozzles are placed to spray down debris on the shed sheets and direct it toward the chip baskets and then to the solution tank. This helps reduce cleaning and maintenance time.

With water-based parts washers, evaporation occurs naturally. Water make-up can be done automatically, eliminating the need for the operator to monitor the solution level. A level sensor actuates a solenoid valve when the solution level is low, allowing water to enter the machine. The pump and heat source will shut off to prevent damage until solution reaches adequate levels.

The Firebar-style electric heating elements feature a flat surface geometry, which reduces scaling, coking, and degrading. Gas burner and steam heating systems are also available.

Alliance’s exclusive drop-in heating elements conserve resources and minimize machine downtime. The design incorporates a submersible watertight stainless steel junction box and tube extension, and is mounted through the top of the tank for quick removal and replacement. Standard heating elements are typically mounted horizontally through the tank sidewall, requiring the tank to be drained prior to inspection or replacement. These elements have an incoloy sheath which resists corrosion, and the flat surface geometry reduces debris build-up, extending the element’s lifespan.

Operating at the correct solution temperature will optimize the cleaning performance and save on energy costs. A thermostat controller allows the operator to adjust the heat setting to achieve the desired operating temperature. Heating elements will automatically cycle on/off to maintain the set temperature.

A horizontal solution pump is available in varying materials and ratings depending on the cleaning application.

A vertical “seal-less” solution pump has no mechanical seals to wear out, and is mounted above the solution tank, minimizing maintenance and machine downtime.

Parts are carried through the washer on a 1″ x 1″ open mesh, flat wire conveyor belt. The open mesh design is durable yet allows for maximum spray and blowoff impingement for optimal cleaning and drying. Stainless steel is standard. Multiple widths, mesh opening sizes, and belt materials are available.

Heavy duty stainless steel rollers with ball bearings support the flat wire conveyor belt. Rollers offer lengthened conveyor belt life and reduced maintenance.

The “Aqualescer” is an oil coalescer with stainless steel parallel plate design for removing floating oils from aqueous cleaning solutions and process tanks. These oil coalescers are also offered in mild steel construction for machine coolant tank applications. Five (5) standard Aqualescer models are available. Sizes range from 0.5 GPM to 3.0 GPM flow rates.

The “Aquaskim” belt-type oil skimmer is designed for removing floating contaminants from parts washer bath, coolant sumps, and other oil-contaminated applications. The unit is constructed of stainless steel, utilizes a 4″ wide stainless steel oil skimmer belt, and has a lift-off fiberglass hood which covers internal components. The Aquaskim can remove up to 6 gal/hr of floating oils, depending upon the viscosity and solution condition.

A belt-type oil skimmer removes floating contaminants from the surface of the solution. The 1” belt is constructed of stainless steel and can remove up to 0.5 gal/hr of floating oils as it passes by a scraper blade.

The exhaust fan system draws steam vapor from inside the washer for venting outside. External ducting is required.

The mist collector exhaust system removes steam from the interior of the machine and vents directly to room atmosphere. Cooler room air is mixed with air from the wash system to assist in reducing moisture in exhaust air. Mist collectors can be used in place of conventional exhaust fans and do not require external ducting.

Ambient blowoff removes gross amounts of moisture from parts. Air knives and/or air manifolds can be configured to be adjustable.

Heated blowoff is used when parts need to exit the machine 100% dry. Air knives and/or air manifolds can be configured to be adjustable.

E-Series models include rear tank access with a removable chip basket for coarse filtration.

Micro-filtration includes an externally mounted filter chamber located on the discharge of the solution pump. A stainless steel inner basket holds a disposable bag that filters 100% of a cleaning solution. Filter bags are available in a range of micron sizes, sized based on the application. Filter chambers are available in a variety of capacities, configurations, and either stainless steel or mild steel construction. A contamination sensor can also be added to monitor filters and trigger an alarm condition.

Cleaning chemistry can be automatically added during operation by a water-driven proportional injector. The chemical injector automatically adds the desired percentage of chemistry, mixing water and chemical prior to entering the solution tank.

Photo-eye product sensors located and the load and unload ends of the washer sense when a part is present on the conveyor. A timer in the control cabinet can be set so that the pumps, blowers, heat, and conveyor turn on or off in sequence depending on the presence of a part.

Front and rear tank access openings allow for easy periodic maintenance and inspection, which is beneficial when rinsing out debris and sediment during tank cleaning.

The split-style drain port is designed to allow complete drainage of the tank for periodic inspection and cleaning. An overflow port is also included.

A light curtain sensor system with mesh guarding can be placed at the load or unload ends of the machine for operator safety. When the light curtain beam is broken, the power is shut off to the conveyor or servo drive to prevent injury.

For many parts cleaning applications, special conveyors may be beneficial. A variety of entrance and exit conveyors can be configured to aid in part loading and unloading. A 180° return conveyor may help reduce labor costs and part handling.

The Alliance DP-series industrial conveyor dip tank parts washer incorporates a dual-zone heated wash with optional blow-off capabilities. The customer’s parts are easily loaded into the low elevation intake chute which resides above the first stage of a dual-stage heated wash configuration. After the parts are processed through the agitated dip zone, they are conveyed upward out of the dip zone through the second stage heated power spray wash zone which allows the wash solution to wash away the contamination from the parts. The parts are further conveyed upward through an optional blow-off zone which dries the parts before they are off-loaded through the discharge chute and into a customer-supplied container.

The DP-series industrial conveyor dip tank parts washer incorporates a unique, ease-of-maintenance hinged conveyor design that lifts upward, providing easy access to the interior of the hot wash tank for periodic cleaning. The machine utilizes a user-friendly relay logic control for easy machine control.