Rotary Indexing Parts Washers

Aquamaster RI

Call us: 1-800-969-7960

The Aquamaster RI rotary indexing industrial parts washers are designed for applications which require critical cleaning of parts with specific features such as blind holes, passageways, hidden cavities, and sensitive surfaces. Rotary indexing parts cleaning systems are intended for use in manufacturing cells, where floor space may be limited. The unique conveyor system allows part loading/unloading from one convenient location and parts can be unloaded manually or robotically.

Request a Quote

Let our team configure the right parts washer for your application.

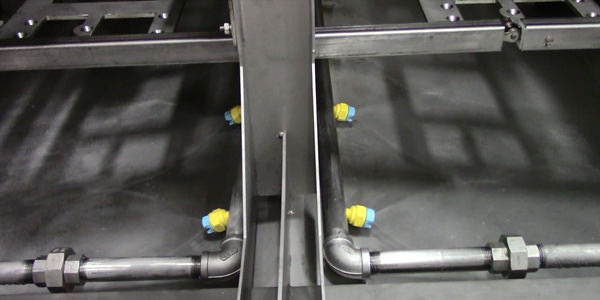

Rotary indexing parts washers utilize custom fixtures to hold manufactured parts securely and in precise positions or orientations for washing, rinsing, and drying. Spray manifolds with strategically positioned nozzles are utilized for flushing out part features such as blind holes, passageways, hidden cavities, and leading/trailing surfaces. Drying is accomplished through the use of high-pressure blowers and timed compressed air for dislodging moisture from part cavities. Moving manifolds and probing devices can also be incorporated for cleaning hard-to-reach areas. The benefit of using part fixtures and indexing is that it allows the cleaning system to specifically target part features that require critical cleaning.

Alliance’s rotary indexing parts washers can be engineered to run in either manual mode or designed to be integrated with robotic load/unload automation devices. Indexing is accomplished through the use of a servo drive conveyor system and sensors to seamlessly communicate with automated loading and/or unloading devices. Sensors also aid in holding tight position tolerances. Electrical controls can be supplied to specification. Our rotary indexing machines have the technology to account for accurate part positioning and maintain proper cycle times; all critical to the operation of an indexing parts washer.